The GFAD1-50 series of combined AFDD &RCBO - Quality approved combined AFDD &RCBO provides the highest degree of protection, safeguarding final circuits against the effects of:Over CurrentResidual CurrentArcing FaultsOver VoltageOver Voltage ProtectionAFDDs can also......

The GFAD1-50 series of combined AFDD &RCBO provides the highest degree of protection, safeguarding final circuits against the effects of:

Over Current

Residual Current

Arcing Faults

Over Voltage

Over Voltage Protection

AFDDs can also mitigate the risk fire caused by faults within the whole electrical Installation, both within the fixed wiring and the cabling of equipment connected to it.

What is an arcing fault?

An arcing fault is defi ned as a “dangerous unintentional arc” within an

electrical circuit which has the intensity and duration to cause localised

heating at the point of the arc.

This high intensity heating can result in localised burning that over

time can generate temperatures exceeding 6000°C, suffi cient to burn

surrounding insulation and eventually allowing a fi re to develop.

Depending upon the nature of the fault, an arcing fault may not develop

immediately, only becoming established over a long period of time

as carbonisation of the surrounding insulation material creates the

conditions for the arc to develop.

Potential causes of arcing faults.

Arcing faults can occur due to several reasons, ranging from poor

installation or accidental damage to cabling and equipment, to

deterioration of the cable over time due to external factors. These faults

can occur within the fi xed cabling installation, or on portable equipment

connected to the fi xed wiring installation.

Electrical arcing faults may be caused by (but not limited to):

• Kinks or breaks in fl exible appliance leads

• Conductor/insulation damage caused by drilling

or construction work

• Incorrect wiring stripping

• Defective plugs and sockets

• Rodents chewing cables

• Damage to cable insulation (exposed or frayed wires)

• Dirty or worn electrical contacts

• Impurities such as corrosion or dust

• Appliance failure

• Poorly maintained electrical systems

• Trapped or Crushed Cables*

• Insulation deterioration due to:

o Incorrect bending radius of cables

o UV deterioration

o Thermal overload

• Loose terminations*

* Note: AFDD’s will detect arcing but not high resistance connections,

or trapped insulation.

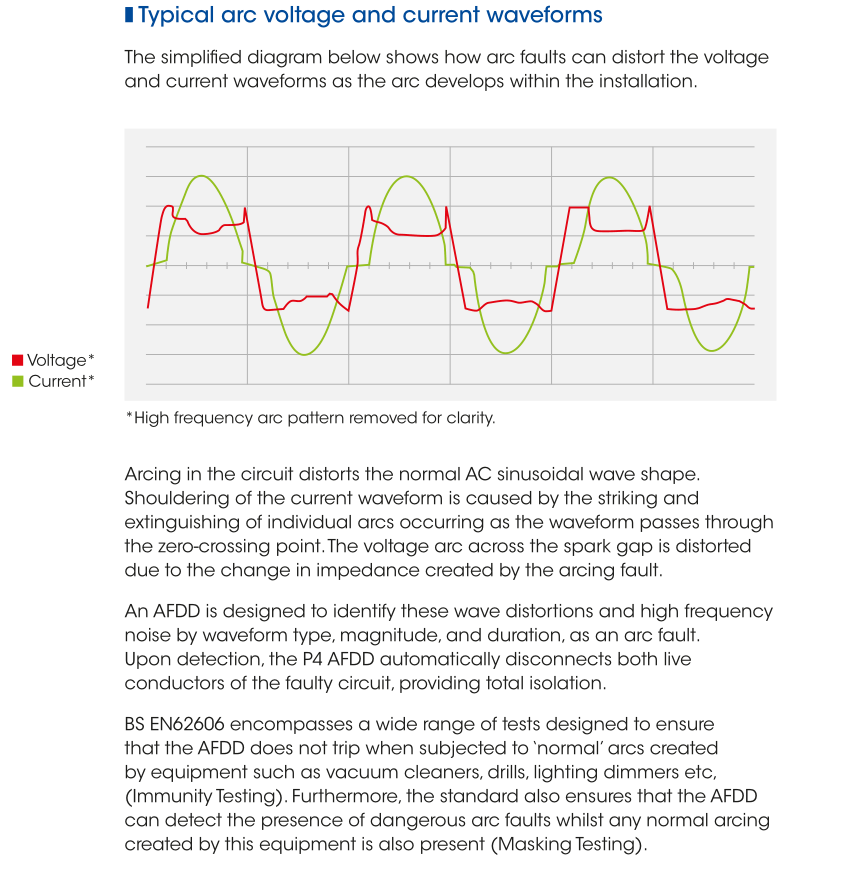

How an AFDD works in detecting dangerous arcing faults.

An AFDD uses microprocessor-based technology to continuously monitor

the electrical circuit, identifying unintentional arcs caused by broken or

damaged cables or poor connections. They can differentiate between

“dangerous arcing” and “normal arcing” caused by switching events or

operation of motor loads.

To achieve this, the AFDD analyses the duration and irregularity of the arc

waveform itself. In this way, the AFDD can distinguish between dangerous

arc faults and arcing caused by normal operation of equipment such as

vacuum cleaners, drills, lighting dimmers etc.

Dangerous arcing consists of a long duration arc which becomes

established and creates suffi cient energy to cause localised ignition, whilst

arcing associated with the normal operation of equipment is of much

shorter duration and would not activate the AFDD.

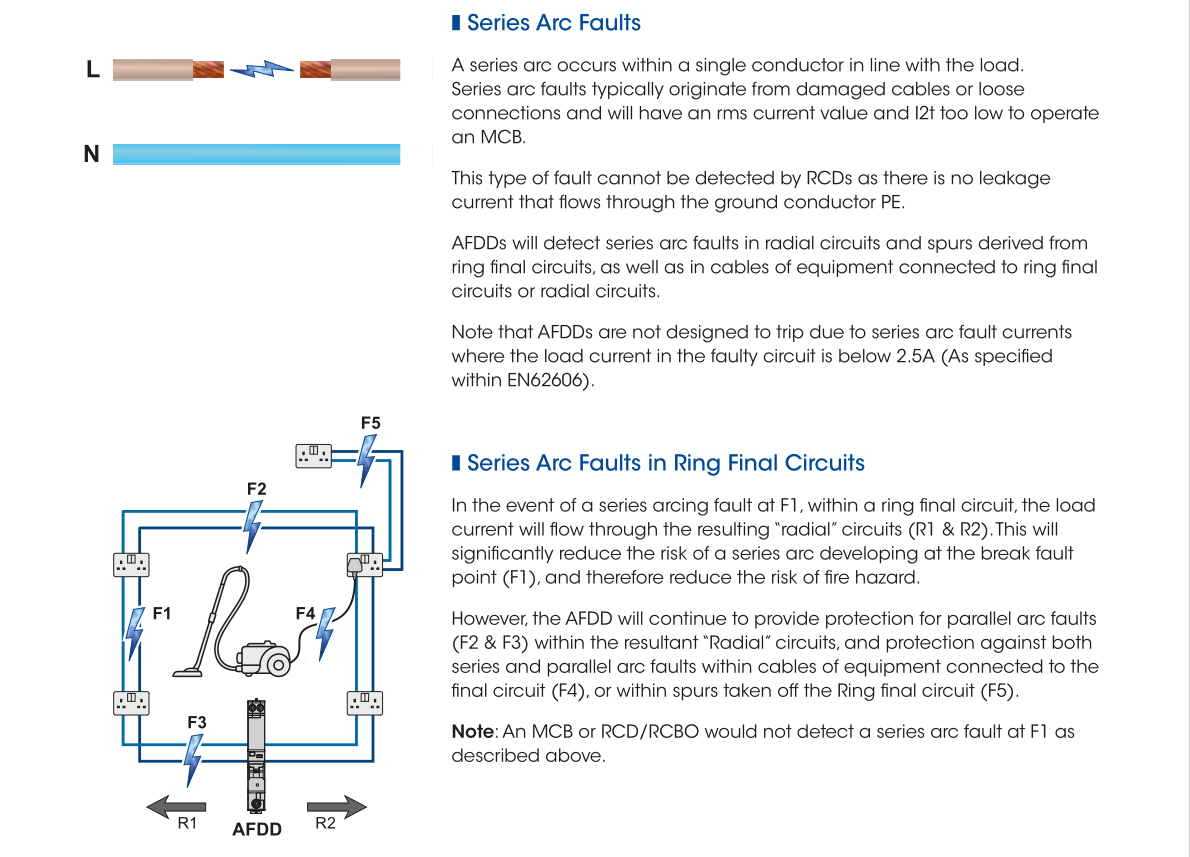

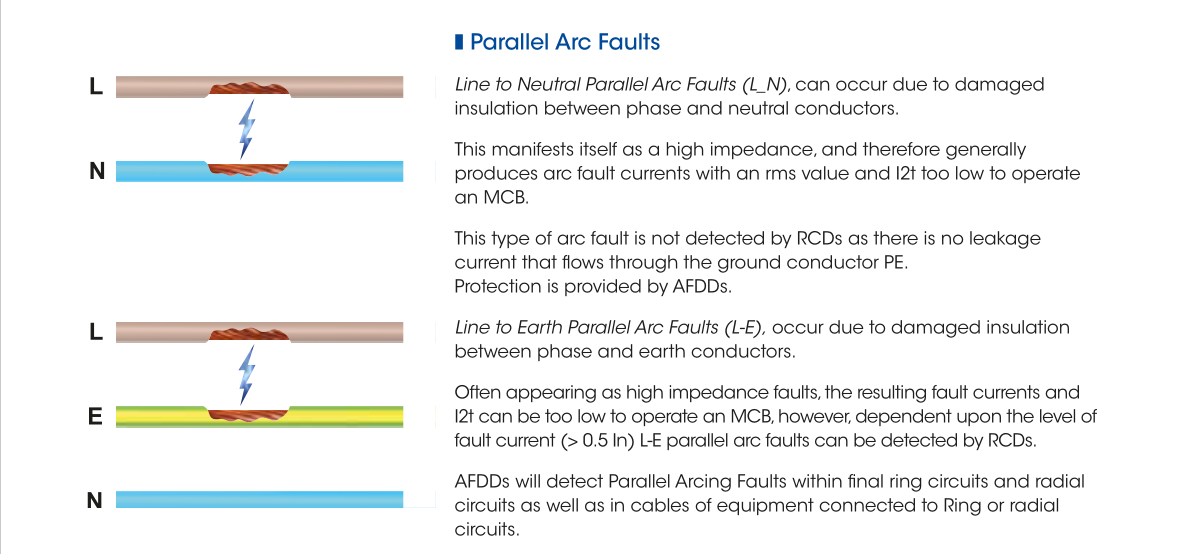

Series and parallel arcing faults.

Arcing Faults can be classifi ed as ‘Series’ or ‘Parallel’.

In general, series arc faults are localised, and fault current is limited by

the connected load, thus remaining within the current rating of upstream

overload protective devices.

Due to the arcing current being in series with the load series, arc fault

currents are signifi cantly lower than those which can be generated by

parallel arc faults.

Parallel arc faults will signifi cantly increase the circuit current, but due to

the inherent high impedance, may not reach the short circuit current

value which would cause operation of an upstream overcurrent protection

device.

The Wiring Regulations BS7671 provides for several levels of protection

against fi re within electrical installations, ranging from the implementation

of basic protection, by defi ning wiring practices, insulation of live parts,

and the inclusion of barriers and enclosures, to the use of fault protection

devices such as MCB’s and RCDs, and more recently the requirement to

install Surge Protection within designated areas.

In addition, there are 2 main areas within BS7671 which relate specifi cally

to the installation of AFDD’s:

The GFAD1-50 series combined AFDD & RCBO.

The GFAD1-50 series combined AFDD & RCBO offers the ultimate

protection for 230V distribution circuits against the effects of:

1. Overcurrent faults (Overload and Short circuit)

2. Residual current faults (30mA type A)

3. Series & Parallel arcing faults

4. Prolonged overvoltage faults

They are designed for integration within the GF range of distribution

boards and are fully interchangeable with the GF range of 6kA single

module MCBs and RCBOs.

Available in current ratings of 6-50A, incorporated within a single module width.

The device combines a microprocessor based AFDD with a 1P+ Switched

Neutral RCBO, incorporating a 30mA class A RCD and a 6kA MCB, and is

suitable for use on TN-S, TN-C-S & TT network systems.

The switched Neutral pole makes the device suitable as a means of double

pole isolation, and is particularly appropriate for installations within TT

Earthing Systems where it is necessary to disconnect all live conductors to

achieve safe isolation of individual circuits (BS7671:2018 Regulation 462).

Lewden AFDD RCBOs are suitable for use 230V 50Hz supplies. They are not

designed for use on DC networks.